Major Industries That Use litho printing Today

Major Industries That Use litho printing Today

Blog Article

A Comprehensive Overview to Understanding Litho Printing Methods

The globe of litho printing, a method stemming from the late 18th century, is an interesting mix of background, development, art and science. Remain with us as we trip right into the fascinating realm of litho printing.

The Historic Development of Litho Printing

The historic trajectory of litho printing, a pivotal advancement in the world of communication, is a captivating story of human resourcefulness. Birthed in the late 18th century by Alois Senefelder, this method was at first an economical technique of releasing theatrical jobs. Lithography, derived from the Greek words for 'stone' and 'to create', made use of a smooth rock surface area to transfer pictures onto paper. The process progressed with the development of the rotary press, which considerably increased efficiency (litho printing). In the 20th century, the development of countered lithography revolutionized the market, permitting automation of top quality prints. Each phase of litho printing's advancement showcases mankind's ruthless quest of performance and high quality in visual communication.

Deciphering the Scientific Research Behind Litho Printing Inks

Moving on in the exploration of litho printing strategies, the emphasis currently shifts to the scientific research behind litho printing inks. The composition of these inks, their drying process, and shade mixing strategies develop the foundation of this complex art kind. Comprehending these aspects is crucial to grasping the craft and achieving the wanted print results.

Composition of Litho Inks

In lithographic printing, the basic role of litho inks can not be overstated. The make-up of litho inks varies depending on its objective, yet usually, they contain 2 major elements - pigments and automobiles. Pigments, the color-providing aspects, are finely ground particles suspended in the lorry, a fluid that brings the pigment onto the printing surface area. The car is a complicated combination of solvents, oils, and materials, which influence the ink's drying out time, bond, and gloss. Additionally, different ingredients are present to enhance certain residential properties like flow, drying out, and resistance to environmental impacts. Each component plays an essential component in the last print's high quality, making the specific formulation of litho inks an elaborate science.

Ink Drying Refine

From the composition of litho inks, attention turns to the interesting procedure of ink drying. Two primary techniques are used in litho printing: oxidative drying out and absorption. Absorption, on the various other hand, involves the ink permeating right into the paper fibers, which is a quicker procedure but can lead to much less vibrant shades.

Color Mixing Methods

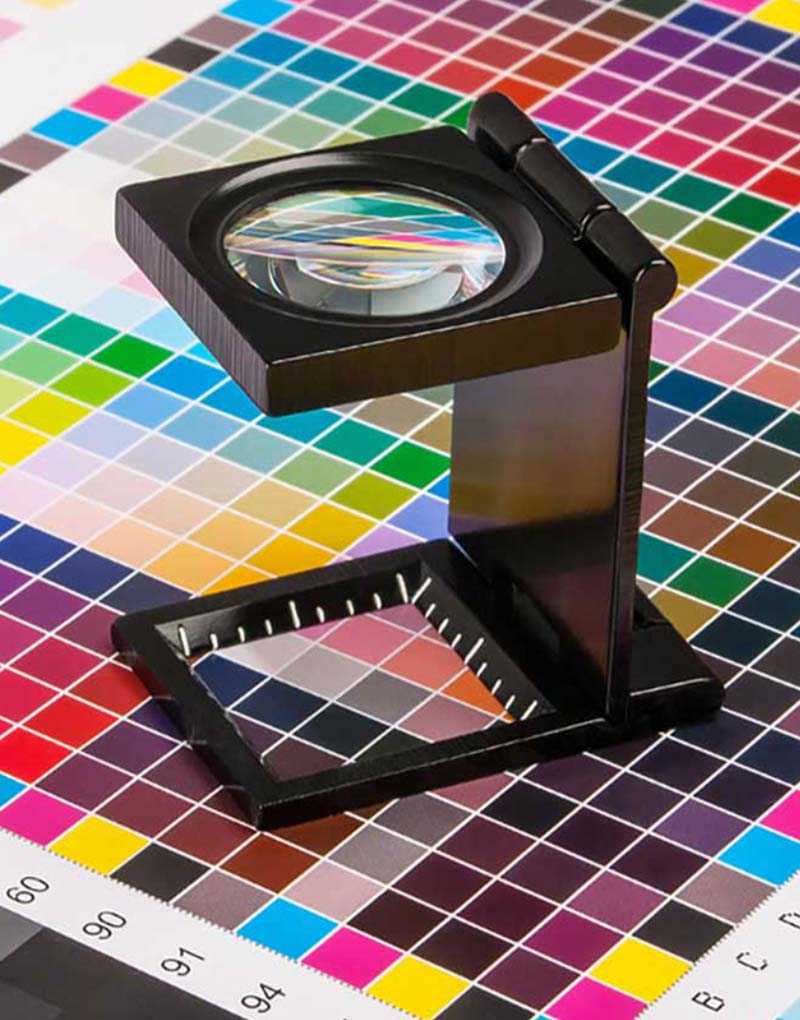

While the drying out procedure plays a vital duty in litho printing, the science of color blending techniques holds equivalent significance. This is a complicated process that entails the cautious blending of main shades: cyan, magenta, and yellow, in differing percentages to achieve a broad array of hues. The addition of black ink, called 'vital', aids in controling the strength and deepness of the shades. The science behind litho printing inks likewise considers the openness of the ink, which impacts just how colors overlay and mix. To achieve an effective shade mix, print experts should also recognize the details of ink habits, color theory, and the physical residential properties of the substrate on which the ink is used.

The Art and Design Aspects in Litho Printing

Litho printing breathes life into art and style via its special aspects. The process entails developing an image on a lithographic limestone plate or metal plate with a smooth surface area. The picture is after that published onto a tool, usually paper, by transferring the ink from home plate. What collections litho publishing apart is its capability to reproduce complex layouts with high integrity, making the outcome virtually similar to the initial artwork. This is accomplished through the usage of different line techniques such as cross-hatching, hatching, and stippling, which enable a series of tonal impacts. Furthermore, litho printing fits a variety of shades, allowing artists to develop dynamic and vivid prints. This combination of accuracy and convenience makes litho printing a recommended choice for lots of artists and designers.

Modern Applications of Litho Printing Strategies

Litho printing techniques have actually discovered comprehensive usage in the contemporary commercial market. Its influence and importance continue to grow with the development of new technologies and innovations in the area. This area will certainly discover these contemporary applications and the transformative duty they play in the printing sector.

Commercial Litho Printing Uses

Litho printing stays an important component of the commercial sector. High-volume printing jobs, such as the production of publications, newspapers, and product packaging, rely on litho printing for its capacity to deliver premium picture high quality and cost efficiency. Litho printing additionally provides a wide shade range, premium to that of electronic their explanation printing.

Technologies in Litho Printing

Pressing the borders of typical strategies, modern-day improvements have fueled a host of technologies in litho printing. One prominent advancement is electronic litho printing, which incorporates the merits of electronic innovation with litho's premium result. These technologies highlight the long-lasting relevance of litho printing in the modern-day globe.

Discovering the Process of Litho Printing: Action by Action

Obstacles and Solutions in Contemporary Litho Printing

In spite of the accuracy and tradition that litho printing happily promotes, it is not without its collection of modern difficulties. Digital litho printing enables for affordable brief runs and easy personalization, dealing with the problem of variable look at this site information. Hence, while there are challenges, the litho printing industry is proactively adapting to satisfy them head-on, ensuring its importance in the future.

Conclusion

In final thought, litho printing, with its abundant background and scientific complexities, holds a significant place in the print industry. The future of litho printing hinges on its capacity to adjust to these transforming needs, attesting its long-lasting value in an advancing market.

Report this page